Air Freight Packaging Guidelines – Optimum Requirements[2020]

Air Cargo Packing Requirements – An Overview

Air freight packaging guidelines aims to point out how to guarantee the freight the maximum possible safety. It should help the cargo withstand quick and rough handling, not only at the airport but also during haulage and warehouse movements. This article will provide a compact set of guidelines or rather points that can guide you. It aims to lead you through in planning the type of packaging and in organising it. The section below gives an idea of factors to be taken into account

Air Freight Packaging Guidelines – Your Attention Please

- Shock from dropping, bumping

- Lateral stress : squeezed by other pieces of freight from the sides

- Vertical stress : resulting from top load, when other pieces of freight are placed on top

- Strap tension : tension applied by binding straps that cut into the package

- Vibration : especially relevant when polystyrene chips are used inside the packaging.

- Damage caused by equipment: forklift can cause damage

- Temperature : high temperatures : Insulation, Humidity

- Elements : rain, water leakage, snow, ice, direct sunshine, heat

- Dangerous goods : only certified packaging may be used

- Wood packaging : need certification, treated wood is a must

- Temperature Sensitive Content – Insulation, “Do Not Freeze” labelling if needed

Anti-Terror Measures – Is Your Package Secure?

All airports and government agencies are tightening safety regulations. Each individual is responsible for helping the authorities in their task of maintaining safety.

You might ask what has packaging requirements to do with anti terror measures. A pertinent question. Can a foreign object such as an explosive be smuggled into the freight? That one question sets the stage for many points concerning freight safety and security.

Each individual is responsible for helping the authorities in their task of maintaining safety.

How to ensure the safety of your freight? – Storage

- Is your warehouse or storage facility kept under 24 hour video surveillance?

- Is the warehouse equipped with an alarm system?

- Is the freight in the warehouse accessible to all and sundry?

- Is there a protocol the defines who may enter the storage space?

- is it mandatory for personnel entering the storage room to sign an entry register?

- Is storage facility kept locked all the time?

- Has a register for administrating keys been set up? Is this register kept under lock and key?

- In case unauthorised personnel need to enter the storage, will that person be accompanied closely, the whole time he is present there?

- Is there a system set up to inspect the surveillance equipment and security measures and document the inspection?

- Has a person been appointed for overseeing the safety system?

- If such a person or persons have been appointed, do they undergo a regular security awareness training program?

- Has such a program been audited for its worthiness?

Your Package is Secured. How About Your Documents?

Not only the packages can be manipulated but the documents as well. Unauthorised persons should not have access to any document that is connected to the freight.

Document Security in Air Freight

The following documents have to be kept under lock and key.

- Invoices

- packing lists

- Deed of sale

- Contracts

- Bank documents

- Freight papers (Waybills)

Manipulation of Freight -Is Your Package Tamperproof?

Any kind of opening, such a hole or a slit is a potential risk. Such openings can be used for smuggling foreign objects, such as an explosive device or a triggering device that can detonate an IED (Improvised Explosive Device) planted elsewhere.

Is your air freight package at risk of manipulation?

If the opening is big enough, that very opening might be used to plant an IED into the package. Security inspectors will, on seeing such an opening, declare the freight as “in danger of manipulation”. Please remember that the warehouse members of staff are authorised to report such a risk and declare the package unfit for further transport. This will result in the piece of freight being forbidden from being processed any further until the package has been inspected and the fault rectified satisfactorily.

Using Wood Packaging Materials (WPM)? IPPC Certified? It is not you will face additional expenditure

Seal the carton flaps with adhesive tape. Close any kind of openings. Check the corners of the cartons and seal any opening. Can any of the flaps be opened very easily? Seal them with strong adhesive tapes.

In Germany the LBA is the authority that is responsible for aviation security It is the office that certifies freight forwarding companies for aviation safety. This office sets forth, amends, improves and enforces the rules that regulate safety in civil aviation. Schiettinger, a company located in Goeppingen, in southern Germany, has developed interesting packaging products that follow the air freight packaging guidelines recommended by LBA.

WPM or SWPM – Wood Packing Material or Solid Wood Packaging Material

If you are using WPM or SWPM, the most important question is: is the wood IPPC certified? Is the wood (in any form) used in conformity with the ISPM regulations? Is the IPPC logo visible clearly on the outside?

Untreated and Uncertified Wood Used in Packaging – The Risks

If uncertified wood has been used in packaging and is brought to light, authorities can seize the freight and order it to be flown back to the airport of origin. The shipper will have to bear the cost of the returned freight.

Damage Prevention – Keeping The Content Safe

Right from the time the package is picked up from your facility, it is out of your reach and can be subject to factors that can potentially cause damage. Your packaging must be suitable to prevent almost all forms of potential damage. A few of the factors are discussed here.

Air Freight Packaging Guidelines – Causes Leading to Damage

Before assessing possibilities of damage, it is important to know how resistant the content of your package is. That assessment will give you the idea of the type of packaging you need to use.

What are the causes of damage to cargo

- Elements : Rain, sun, wind, humidity, dust

- Stress – Vertical, horizontal and lateral during movement

- Movement – Dropping, tumbling, throwing

Damage Caused by Elements

Rain and humidity : contents can wet and mouldy. Sun might cause discolouration or damage sensitive parts. Dust can damage electronic components!

Stress as Damage Factor

An air freight package is subject to movement during transport. While the package is in motion it can be subject to mainly two types of stress :

- Horizontal stress

- Vertical stress

Horizontal and Lateral Stress on Air Cargo Packaging And Content

Horizontal stress :A vehicle moving forward exerts stress in a horizontal direction on the air cargo it is carrying. Forward motion results in the velocity acting backwards (Newton’s third law of motion :Every action has an equal and opposite reaction). This velocity that is transferred to the freight acts on the content of the package.

If the content is not tightly secured inside the outer packaging, the transferred velocity moves the content in the opposite direction of the vehicle. This constant motion can damage the goods. In the image below, one can see the how the items that were not secured moved along the horizontal line of movement.

Lateral stress : Lateral stress is caused by sideways movement. A lorry taking a turning to the left will generate a counter velocity to the right. If the freight is not secured inside the hold, this counter velocity will move the freight. The speed of the vehicle will determine the strength of the crash the freight will experience. Even if the freight is firmly secured, the freight will still experience the pressure of the movement.

A lateral stress can also be caused by other pieces of freight pressing against the packet as the vehicle moves. The weight of the packages will be transferred to the freight on which the former collides.

You may access, here, the best practices for road transport published by the European Union.

Vertical Stress – Stacking, Top-Load

When freight is stacked, the pieces on the top exert their weight on the ones below. If the pieces below the top one are too weak the latter will get damaged. If the packaging is not sturdy enough to absorb and distribute the weight evenly, the contents can suffer damage.

Dangerous Goods in Air Cargo Shipping

This is a specialised category in itself. Even a large article is not sufficient to explain the requirements.

All goods that are classified as dangerous goods must follow the Dangerous Goods Regulations published by IATA.

Dangerous Goods are to packaged exclusively in certified packaging materials. The packaging may be done only by certified person / company holding a valid certification. Internet guidelines are NOT enough.

Cargo Packaging on Pallets, Crates – Can a forklift move them?

Using pallets or crates is a good decision. However, air freight rates specify “forkliftable” (a new term). That means the pallet or crate must have a possibility for the forks to go beneath the freight.

Dimensions are always written as Length x Width x Height

Dimensions Can Influence Transit Time

Give your air cargo package the maximum flexibility by planning the dimensions. Not all aeroplanes are freighters (aircraft that transport only freight). On passenger aircraft the freight is loaded into the belly, the compartments below the flight deck, where the passengers sit. On long haul flights, the standard maximum permissible height of the air freight package is 160 cm. Any package with a height of more than 160 cm cannot be loaded.

On short haul flights the maximum permissible height is even lower. on a Boeing 757, it is 70 cm, on Airbus A318/A319/A320 it is 110 cm.

Palletising Cartons Freight – Safe, Secure and Stable

Planning In Advance – Well Prepared is Half Done

Before you plan your pallet, plan your cartons according to your products, i.e. the content. The content must fit snugly into the cartons. Leave no room for movement. The items will not move on their own. Think about the law of inertia by Newton. A body at rest or a body in motion will continue to remain in that state until acted upon by an external force.

Air Freight Package – Weight and Volume Weight

The dimensions of your freight are important! It is not only the weight that counts. You are paying for the space (volume) your freight occupies in the aircraft. This is the reason why freight forwar4ders mention the term chargeable weight, that is the weight on which air freight price is charged.

How to Calculate Volume Weight

Multiply the dimensions and divide by 6000. The result is the volume weight. Compare this to the gross weight (the weight of your package). Whichever is the higher value, that is the chargeable weight.

Here is an example: A package with a dimension of 120x120x120 cm (Length x Width x Height) weighs 175 kg. (120 x120 x120) / 6000 = 288. The volume weight is 288 kg. 288 is greater than 175. Hence, your air freight rate is calculated on 288 kg. If your air cargo rate is 2.50 per kg chargeable weight then:

2.50 x 288 = 720.00

The values are rounded off to the next half a kilo. That means : 288.4 will be 288.5 kg, 288.5 remains unchanged and 288.6 becomes 289.00 kg

How to Calculate The Volume in Cubic Metres

Volume in cubic metres is calculated by multiplying the dimensions in metres. Dividing the value by 166.66666 will give you the volume weight. Do not round up to 167.00! Cubic metres is written as cbm.

From the above example : 120 x120 x120 cm will become 1.20 x 1.20 x 1.20 m = 1.728 cbm. The volume of the freight is 1.728 cbm. Multiply this by 166.666 and you get the chargeable weight :

1.728 x 166.6666 = 288.00 kg

Chocks (feet) of the pallets

Read more about this in the article on floor load tolerance capacity limits. The cocks must be protected by a slat to help uniform distribution of weight.

Avoid Overhang When Using Pallets

The freight should not exceed the perimeter of the pallet.When the freight exceeds the size of the pallet, we have an instance of overhang. An overhang is a potential risk and can result in damage.Use straps to fix the freight firmly on the pallet. The freight and the pallet must be bound together by the straps.

Here is an excellent video that explains clearly how to palletise your freight.

Credit: Palletways

Edge Protection Collars for Cartons

Straps might cut into the sides of the cartons. This might damage the content or expose the content to damage caused by external factors.

Good Freight Packaging Practices

Dimensions – Think of Security Screening

The warehouse staff will do an x-ray screening of your package, if the authorities have not classified you as a Known Shipper. Most of the X-ray machines have a maximum width of 155 cm and a maximum height of 155 cm. If your package is bigger than that a manual inspection is mandatory. A standard test is ETD (Explosive Trace Detection)

Packing List on each package

Put yourself in the shoes of the consignee’s customs broker. It is he who has the first access to your consignment. He needs to file the customs bill of entry. This requires details of thee content. Attach a packing list to each package in such a way that it does not get lost.

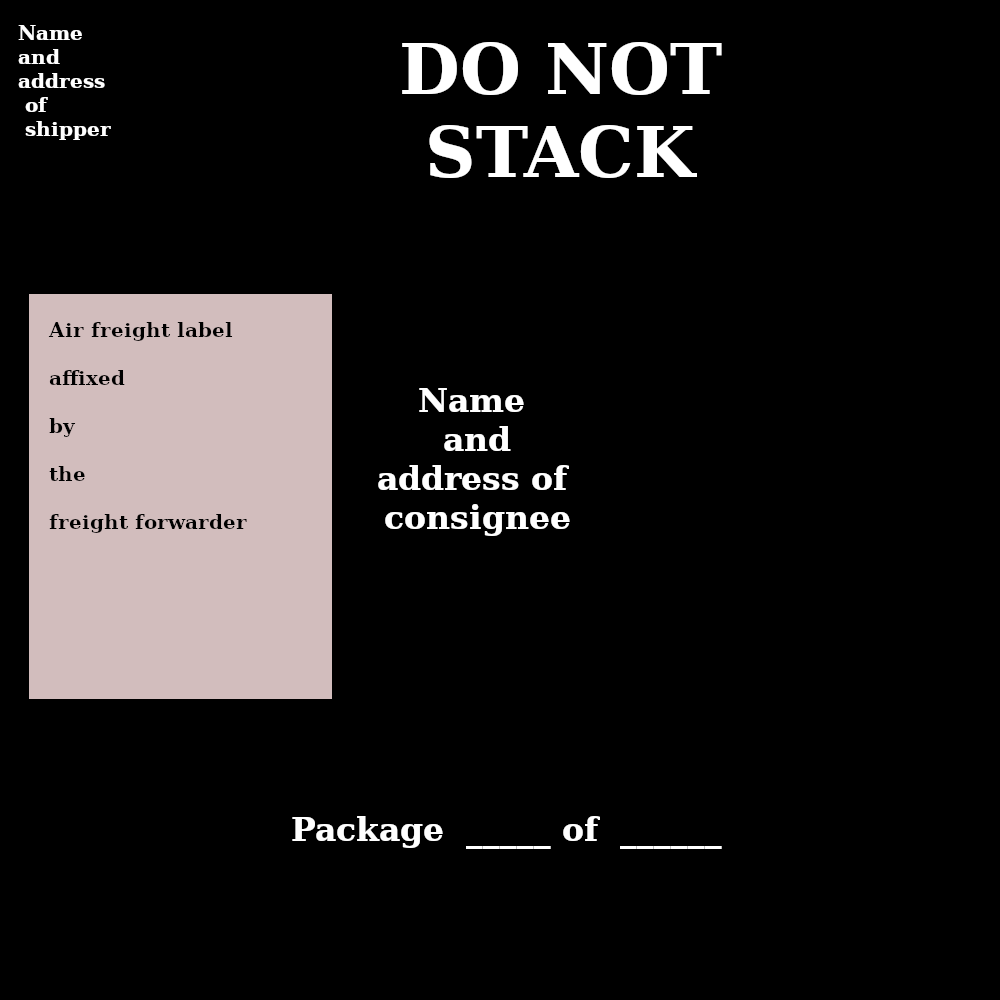

More than one package in the shipment?

Attach number labels. Remember, the airlines move thousands of pieces in a day and your packages are a part of that large quantity. The members of the warehouse staff need to be fast. They need to sort, group and arrange freight so that nothing goes missing. Mark your packages clearly, so that identifying them and grouping them becomes easy.

Content of the the Freight Consists of various items

Attach a detailed list with number of each item, nett weight and description. This will help customs clearance, if there is a case of short-landing (not all the pieces of the freight arrives on a single flight). DO NOT DO THIS IF THE ITEMS ARE EXTREMELY VALUABLE.

Short Summary of Air Freight Packaging Guidelines

Use sturdy packaging materials. Use safety measures by securing the content against shocks and stress. Use waterproofing, if needed. If the contents are fragile, use a “FRAGILE” label, on all sides. Additionally attach DO NOT STACK labels. If the contents are temperature sensitive, label the package accordingly. Use only certified packaging for dangerous goods and use the services of a certified packaging company to do the packaging. Use correct labelling. Seal all openings. Use tamper proof packaging materials. Keep the freight safe from unauthorised persons. Storage facilities should be under video surveillance. Documents should be under lock and key.

A Small But Important Point to Note

Customs brokers process a lot of air cargo on any given working day. There are, often, days, when a working day is too short to finish their task. The brokers deal with a lot of papers and data. Shippers can help by paying more attention to their commercial invoices and packing lists. Brokers need clear information to prepare the Customs Bill of Entry. Hence, it is important to keep your invoices well defined.

Packing lists should contain the number of cartons of each item and also include, besides gross weight, the nett weight of each class of items. Ideally the items should be sorted as per their respective HS Codes.